| Items |

LSE1003

10HP Laboratory Oiless Scroll Enclosed Simplex Air Compressor with Premium Controls

|

LSE1504

15HP Laboratory Oilless Scroll Enclosed Simplex Air Compressor with Premium Controls

|

LSE2005

20HP Laboratory Oilless Scroll Enclosed Simplex Air Compressor with Premium Controls

|

|

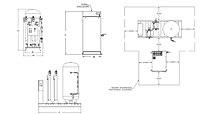

Dimension A

|

N/A

65 in

|

N/A

65 in

|

N/A

79 in

|

|

Dimension B

|

N/A

26 in

|

|

Dimension B1

|

N/A

39 in

|

|

Dimension B2

|

N/A

32 in

|

|

Dimension C

|

N/A

61 in

|

|

Dimension C1

|

N/A

57 in

|

N/A

77 in

|

N/A

84 in

|

|

Inlet Size1

|

N/A

1 in

|

|

Outlet Size

|

N/A

1/2 in

|

N/A

1/2 in

|

N/A

3/4 in

|

|

Power

|

N/A

10 hp

|

N/A

15 hp

|

N/A

20 hp

|

|

Air Flow at 100 psig2

|

N/A

15.2 scfm

|

N/A

30.4 scfm

|

N/A

45.6 scfm

|

|

Tank Capacity

|

N/A

80 gal

|

N/A

120 gal

|

N/A

200 gal

|

|

Compressor Capacity3

|

N/A

12,725 Btu/hr

|

N/A

25480 Btu/hr

|

N/A

38180 Btu/hr

|

|

Noise Level4

|

N/A

53 dBA

|

N/A

56 dBA

|

N/A

58 dBA

|

|

System Full Load Current (F.L.A) at 208 V

|

N/A

30.4 A

|

N/A

44.6 A

|

N/A

58.8 A

|

|

System Full Load Current (F.L.A) at 230 V

|

N/A

27.6 A

|

N/A

40.4 A

|

N/A

53.2 A

|

|

System Full Load Current (F.L.A) at 460 V

|

N/A

13.8 A

|

N/A

20.2 A

|

N/A

26.6 A

|

|

System Weight

|

N/A

1350 lb

|

N/A

1700 lb

|

N/A

2050 lb

|

|

Brands

|

N/A

Powerex®

|

|

Type

|

N/A

Simplex

|

|

Warranty (Limited)

|

N/A

3 years

|

|

Electrical Panel Opening

|

N/A

42 in

|

|

Minimum Clearance for Ease of Maintenance

|

N/A

24 in

|

|

Dew Point Temperature

|

N/A

-40 ºF

|

|

Stages

|

N/A

2

|

|

High Alarm

|

N/A

-20 ºF28.8 ºC

|

|

Economy Mode

|

N/A

-45 ºF

|

|

Fixed Mode

|

N/A

-40 ºF

|

|

Pipe Material

|

N/A

Brass Stainless Steel Type K Copper

|

|

Control Panel Protection

|

N/A

NEMA 12

|

|

Industry Standards/Certifications

|

N/A

ASME EISA FDA

|

|

General

|

N/A

Each system is completely tested before shipment and includes:

- Multiple oil-less scroll air compressors and associated equipment

- Corrosion resistant air receiver

- Desiccant air dryers with purge control

- Control panel

- Dew point monitor

System installation requirements:1. Main power connection to master control panel 2. Interconnecting power wiring between master panel, each compressor unit, and tank/dryer skid 3. Control signal wiring between master panel and each compressor unit 4. Remote inlet air connection to each module - minimum 1.5" NPTF 5. Interconnecting plumbing connections between each compressor and tank/dryer skid

|

|

Oilless Scroll Compressor Pumps

|

N/A

Each compressor shall be belt driven oil-less rotary scroll single stage, air-cooled construction with absolutely no oil needed for operation. Direct drive compressors shall not be used.

- The rotary design shall not require any inlet or exhaust valves and shall be rated for 100% continuous duty

- Tip seals shall be of a composite PTFE material and be rated for 10,000 hours operation.

- Compressor bearings shall be external to the air compression chamber and shall all be serviceable for extended compressor life. Bearing maintenance shall not be required until 10,000 run hours. Compressors with bearings that are not accessible for service have a limited life span and shall not be accepted. Compressors shall have an integral radial flow fan for cooling and shall not require any additional electric cooling fans.

- Each compressor shall have flexible connectors on intake and discharge, an electric drive motor, a discharge check valve, an air-cooled aftercooler and a high discharge temperature shut down switch.

|

|

Motor

|

N/A

Each compressor shall be belt driven by a TEFC, NEMA construction motor. Motors are EISA compliant and premium efficient.

|

|

Main Controls

|

N/A

The main control panel provides power to the dryer skid, monitors, and the scroll enclosure controls. The main control panel has all the alarm contacts and operations. The system Main control panel features include the following:

For Simplex (LSE) Systems:

- NEMA 12 Enclosure

- UL508A listing for main control panel, UL1450 for compressor enclosure

- Single point connection for incoming three phase power via main power distribution block

- Circuit breaker disconnect with lockable handle provides circuit protection for each scroll enclosure

- Control voltage transformer with fused primary and secondary protection provides power to air quality monitor(s), desiccant dryers, and receiver drain

- Low pressure switch

- System alarms to include audible and visual indication along with dry contacts for each of the following:

- Low pressure alarm

- General fault (indicates High Temp or overload trip from each enclosure)

- Dry contacts for air quality monitor(s)

- Panel door to include:

- Alarm lights

- Horn

- Acknowledge button

- 3-position dryer switch “Dryer#1-Both-Dryer#2”

- Power “ON” light

- Enclosure power disconnect handle

For Duplex (LSED) Systems:

Include all features listed above for simplex systems with the following additional features:

- Dual control transformer with auto switching circuit

- Lag pressure switch

- PLC control for alternation

- Low pressure backup circuit

- Lighted HOA for each enclosure

|

|

Scroll Enclosure Controls

|

N/A

The controls operate the simplex or duplex air compressor modules as needed in response to a pressure signal from a pressure transducer located in the system manifold. An illuminated on/off push button controls power to the motor starters. When the button is in the off position, the system is merely in stand-by mode, not powered off.

The pressure transducer sends a signal to the programmable logic controller (PLC) which is programmed to operate two, three or four compressor modules as needed to maintain the system pressure requirements. An HMI touch screen interface displays system status and alarm conditions. Pressure settings are user adjustable within factory predetermined setting limits.

The PLC will alternate each compressor module based on demand as well as timed alternation. If a compressor module is running longer than ten minutes continuously, the control will alternate to the next available compressor module to equalize run time and synchronize maintenance intervals. On initial start up or if air pressure drops rapidly, simultaneous motor starts are prevented by a programmed three second stagger. One 120 VAC control circuit transformer with primary and secondary fuses is installed for control circuit voltage.

Motor circuit breakers with lockable disconnects are provided for each compressor module. Operating hours, high temperature alarms, motor overload alarms, run indication, and hours to scheduled maintenance for each compressor module are displayed on the screen. All alarm history is kept in the alarm log. Easily navigated menus are provided to allow the user to select the display conditions and acknowledge the alarms. Remote alarm contacts are provided as shown on the system wiring diagram.

The Scroll Enclosure Controls also come standard with the addition of a gateway server card and an ethernet port for connection to BacNet® server or direct connection to facility Ethernet for viewing of system operations and status via device IP-address. This gateway server card connects to the building automation communication gateway with BacNet® protocol and Web server features. Web server features include email notifications in case the system is in alarm or has achieved one of its maintenance intervals and requires service.

|

|

Inlet Filters

|

N/A

The system includes a single inlet filter with a pleated element and a canister with silencing tubes. The single inlet filter serves all the compressor modules in the system. The filter is located inside the sound reducing cabinet protected by a convenient access panel.

|

|

Sound Reducing Enclosure

|

N/A

The system is constructed with an internal frame and steel base system with individual vibration isolation mounted compressor modules. The sound reducing enclosure has a front access panel to allow service of the electrical controls. The enclosure has rear cooling air intake and all exhaust air leaves the enclosure from the top

|

|

Air Receiver

|

N/A

The system shall include an ASME air receiver rated for 200 psi MAWP. The tank shall be equipped with:

- A pressure gauge and a safety relief valve

- By-pass valves to allow tank isolation without system shutdown

- An automatic electronic tank drain with manual override

The receiver shall be internally lined with an FDA approved material for corrosion resistance.

|

|

Air Purification Package

|

N/A

The air purification package shall consist of the following: dual desiccant air dryers, dual filter and regulator bank with sample ports, and dew point monitor with alarms, and all bypass piping. Piping to be brass, stainless, or type K copper, and cleaned for medical air use. All components shall be mounted piped and wired to the air receiver.

|

|

Desiccant Air Dryers

|

N/A

The twin-tower, heatless desiccant air dryer shall yield a pressure dew point of -40 degrees F. The dryer shall be installed and plumbed on a common steel skid to the air receiver. The dryer design shall be of the automatic pressure swing, heatless, regenerative type and shall include a solid state cycle timer, reliable switching valve design, and purge muffler for quiet operation. Dryer controls shall include on/off/variable mode selector switch and digital display with cycle mode counter.

The filtration system shall consist of 2 stages of filtration mounted and plumbed to the air dryer. The first stage of filtration shall include a 0.01 micron coalescing pre-filter with element change indicator and automatic condensate drain and installed up-stream of the air dryer. The second stage shall include a 1 micron particulate filter with element change indicator and installed downstream of the air dryer.

|

|

Dew Point Monitor

|

N/A

The system-integrated hygrometer shall be equipped with an LCD dew point display and high dew point alarm with dry contacts connected to main controls panel. The sensor shall include an auto calibration feature to ensure the accuracy of the dew point measurement. Alarm set points as follows:

- High Alarm: -20 ºF (28.8 ºC)

- Economy Mode: -45 ºF

- Fixed Mode: -40 ºF

|

|

Moisture Separator

|

N/A

The moisture separator shall be sized for the peak calculated demand and shall include an auto float drain to purge the collected moisture.

|

|

Optional Co Monitor

|

N/A

Carbon monoxide (CO) monitor is in an enclosure with LCD display of CO concentrations. The monitor shall continuously display the CO content of the discharge air and shall provide audible and visual high CO alarms. High alarm is set at 10 ppm. Dry contacts are provided for remote monitoring of the high CO alarm on the main control panel.

|