| Items |

PF 0085 SP-N

Culinary Steam Filters

|

PF 0120 SP-N

Culinary Steam Filters

|

PF 0170 SP-N

Culinary Steam Filters

|

PF 0460 SP-N

Culinary Steam Filters

|

PF 0850 SP-N

Culinary Steam Filters

|

|

Shipping Weight

|

N/A

2.1 lb4.6 lb

|

N/A

2.3 lb5.1 lb

|

N/A

3.3 lb7.3 lb

|

N/A

5.5 lb12.1 lb

|

N/A

6.9 lb15.2 lb

|

|

Maximum Rated Flow

|

N/A

30 lb/hr

|

N/A

95 lb/hr

|

N/A

175 lb/hr

|

N/A

750 lb/hr

|

N/A

1250 lb/hr

|

|

Inlet and Outlet Connection Size

|

N/A

1/2 in NPTF

|

N/A

3/4 in NPTF

|

N/A

1 in NPTF

|

N/A

2 in NPTF

|

N/A

2-1/2 in NPTF

|

|

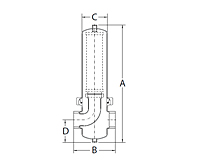

Dimension A

|

N/A

9.444 in

|

N/A

9.444 in

|

N/A

11.397 in

|

N/A

19.016 in

|

N/A

29.528 in

|

|

Dimension B

|

N/A

4.252 in

|

N/A

4.921 in

|

N/A

4.921 in

|

N/A

6.693 in

|

N/A

7.165 in

|

|

Dimension C

|

N/A

2.756 in

|

N/A

2.756 in

|

N/A

3.346 in

|

N/A

4.094 in

|

N/A

4.094 in

|

|

Dimension D

|

N/A

2.239 in

|

N/A

2.239 in

|

N/A

2.774 in

|

N/A

3.642 in

|

N/A

3.799 in

|

|

Replacement Element Kit

|

N/A

E 102 SP

|

N/A

E 102 SP

|

N/A

E 105 SP

|

N/A

E 110 SP

|

N/A

E 120 SP

|

|

Particle Removal at 100% Pleated Depth PP

|

N/A

1 Micron

|

|

Minimum Removal Efficiency

|

N/A

99 %

|

|

Maximum Continuous Operating Temperature

|

N/A

392 ºF

|

|

Maximum Design Operating Pressure

|

N/A

232 psig

|

|

Initial Clean Pressure Differential

|

N/A

1.0 psid

|

|

Standard Body Housing Materials

|

N/A

1.4301 Quality 304 Stainless

|

|

Optional Body Housing Materials

|

N/A

1.4404 Quality 316L Stainless

|

|

Standard Polishing Housing Materials

|

N/A

Passivated and Polished to Grade Ra <1.6 µm

|

|

Optional Polishing Housing Materials

|

N/A

Passivated and Polished to Grade Ra <1.6 µm

|

|

Standard Seals Housing Materials

|

N/A

Aseptic EPDM

|

|

Optional Seals Housing Materials

|

N/A

Consult Factory

|

|

Standard Inlet and Outlet Connections Materials

|

N/A

NPT (Female)

|

|

Optional Inlet and Outlet Connections Materials

|

N/A

Tri-Clamp Sanitary

|

|

Standard Drain and Vent Connections Materials

|

N/A

1/4 in BSPP

|

|

Optional Drain and Vent Connections Materials

|

N/A

1/4 in BSPP

|

|

Standard Element to Housing Connections Materials

|

N/A

Dual O-Ring Positive Click Lock Seal

|

|

Optional Element to Housing Connections Materials

|

N/A

Dual O-Ring Positive Click Lock Seal

|

|

Standard Media Element Materials

|

N/A

Pleated 316 Stainless Steel Mesh

|

|

Optional Media Element Materials

|

N/A

Pleated 316 Stainless Steel Mesh

|

|

Standard Media Support Element Materials

|

N/A

316 Stainless Steel Cage

|

|

Optional Media Support Element Materials

|

N/A

316 Stainless Steel Cage

|

|

Standard Endcaps Element Materials

|

N/A

316 Stainless Steel

|

|

Optional Endcaps Element Materials

|

N/A

316 Stainless Steel

|

|

Standard Seals Element Materials

|

N/A

Dual Silicone O-Rings

|

|

Optional Seals Element Materials

|

N/A

Dual Silicone O-Rings

|

|

Industry Standards/Certifications

|

N/A

FDA

|

|

Applications

|

N/A

Food Processing Beverage Dairy Biotechnology Aseptic Processing

|

|

Additional Information

|

N/A

The unique pleated stainless steel elements incorporate a positive double o-ring click-lock seal and are 100% integrity tested prior to shipment for reliable performance.

High performance filtration for the food and beverage industry.

With high efficiency and low pressure drop these filters provide efficient, cost effective performance exceeding 3A culinary specifications. There is no better filter for your culinary steam needs.

|

|

Note

|

N/A

All materials conform to 21CFR Part 177 of the US code of Federal Regulations and USP Class VI Biological test for plastics.

|