| Items |

NDL-010

3 scfm nano D-Series1 Compressed Air Dryer

|

NDL-020

5 scfm nano D-Series1 Compressed Air Dryer

|

NDL-030

10 scfm nano D-Series1 Compressed Air Dryer

|

NDL-040

15 scfm nano D-Series1 Compressed Air Dryer

|

NDL-050

24 scfm nano D-Series1 Compressed Air Dryer

|

|

Description

|

N/A

Clean and dry compressed air is easily achieved with the new range of nano D-Series1 ultra-high purity compressed air dryers.

|

|

Shipping Weight

|

N/A

18 lb

|

N/A

18 lb

|

N/A

28 lb

|

N/A

36 lb

|

N/A

43 lb

|

|

Maximum Rated Flow (Inlet)1

|

N/A

3 scfm

|

N/A

5 scfm

|

N/A

10 scfm

|

N/A

15 scfm

|

N/A

24 scfm

|

|

Maximum Rated Flow (Outlet)2

|

N/A

2.4 scfm

|

N/A

4 scfm

|

N/A

8 scfm

|

N/A

12 scfm

|

N/A

19 scfm

|

|

Inlet and Outlet Connections

|

N/A

3/8 in. Push to Connect

|

N/A

3/8 in. Push to Connect

|

N/A

3/8 in. Push to Connect

|

N/A

3/8 in. Push to Connect

|

N/A

1/2 in. Push to Connect

|

|

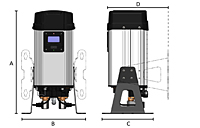

Dimension A

|

N/A

17 in

|

N/A

17 in

|

N/A

25 in

|

N/A

35 in

|

N/A

43 in

|

|

Dimension B

|

N/A

9 in

|

|

Dimension C

|

N/A

6 in

|

N/A

6 in

|

N/A

6 in

|

N/A

13 in

|

N/A

13 in

|

|

Dimension D

|

N/A

10 in

|

|

Model with Energy Saving Dewpoint Sensor

|

N/A

NDL-010-ES

|

N/A

NDL-020-ES

|

N/A

NDL-030-ES

|

N/A

NDL-040-ES

|

N/A

NDL-050-ES

|

|

Service Kit (Desiccant Cartridges)

|

N/A

NDK-010

|

N/A

NDK-020

|

N/A

NDK-030

|

N/A

NDK-040

|

N/A

NDK-050

|

|

IS08573 - 1: 2001 Quality Classes

|

N/A

Dirt: Class 2 (1 micron) Water: Class 2 (-40 ºF/-40 ºC Pressure Dewpoint)

|

|

Allowable Working Pressure

|

N/A

58 to 232 psi

|

|

Allowable Inlet Temperature

|

N/A

34.7 to 122 ºF

|

|

Alternating Current (AC) Voltage

|

N/A

100 to 240 V

|

|

Power Supply Frequency

|

N/A

50 to 60 Hz

|

|

Correction Factor K1 at 60 psi Inlet Air Pressure

|

N/A

0.63

|

|

Correction Factor K1 at 75 psi Inlet Air Pressure

|

N/A

0.75

|

|

Correction Factor K1 at 90 psi Inlet Air Pressure

|

N/A

0.88

|

|

Correction Factor K1 at 105 psi Inlet Air Pressure

|

N/A

1

|

|

Correction Factor K1 at 115 psi Inlet Air Pressure

|

N/A

1.13

|

|

Correction Factor K1 at 130 psi Inlet Air Pressure

|

N/A

1.25

|

|

Correction Factor K1 at 145 psi Inlet Air Pressure

|

N/A

1.38

|

|

Correction Factor K1 at 160 psi Inlet Air Pressure

|

N/A

1.50

|

|

Correction Factor K1 at 175 psi Inlet Air Pressure

|

N/A

1.63

|

|

Correction Factor K1 at 190 psi Inlet Air Pressure

|

N/A

1.75

|

|

Correction Factor K1 at 205 psi Inlet Air Pressure

|

N/A

1.88

|

|

Correction Factor K1 at 220 psi Inlet Air Pressure

|

N/A

2.00

|

|

Correction Factor K1 at 232 psi Inlet Air Pressure

|

N/A

2.13

|

|

Correction Factor K2 at 75 ºF Inlet Air Temperature

|

N/A

1

|

|

Correction Factor K2 at 95 ºF Inlet Air Temperature

|

N/A

1

|

|

Correction Factor K2 at 104 ºF Inlet Air Temperature

|

N/A

0.97

|

|

Correction Factor K2 at 113 ºF Inlet Air Temperature

|

N/A

0.88

|

|

Correction Factor K2 at 122 ºF Inlet Air Temperature

|

N/A

0.73

|

|

Correction Factor K3 at -4 ºF Pressure Dewpoint

|

N/A

1.10

|

|

Correction Factor K3 at -40 ºF Pressure Dewpoint

|

N/A

1

|

|

Correction Factor K3 at -100 ºF Pressure Dewpoint

|

N/A

0.70

|

|

Features

|

N/A

D-Series1 dryers reliably give you:

- More for your money - everything needed for installation is in the box

- Moisture & particulate protection of your production process

- Lower life cycle costs - low energy costs and simplified maintenance

- Built in dewpoint monitoring (optional)

- Space saving - can be easily wall mounted

- Safe and quiet operation

- Peace of mind - The most reliable product of its kind

|

|

Clean and Dry

|

N/A

Clean and dry compressed air is essential in every efficient and profitable manufacturing and process operation worldwide. nano-purification solutions' vast experience includes food, beverage, chemical, laboratory, medical and natural gas applications.

n-psi understands your needs and has created the nano range of high-performance, energy-saving compressed air and gas purification products to provide clean and dry compressed air and gases at an affordable price with unrivaled reliability.

|

|

Design

|

N/A

Our experienced team of design engineers are world leading specialists in the design of new and unique industrial compressed air treatment products and compressed air dryers.

|

|

Research and Development

|

N/A

A core element of our capabilities - founded on cumulative decades of practical engineering expertise - our R&D team is continually looking for improved performance and reliability.

|

|

Manufacture

|

N/A

Ultra-high purity compressed air dryers are manufactured at our state of the art facility to the highest standards of build quality to ensure equipment reliability and high levels of performance.

|

|

Guaranteed Performance

|

N/A

- The nano D-Series1 dryers have been 100% function and performance tested at the factory to ensure the highest standard of performance, delivering compressed air purity in accordance with ISO8573:1 – 2001, Class 2 dirt (1 micron) and Class 2 water (-40 ºC pressure dewpoint).

|

|

Reliable Operation

|

N/A

- High efficiency moisture removal and reliable operation with PLC controlled solenoid valves

- Integral volumetric flow limiter prevents overflow ensuring consistent dewpoint performance

- Condensate is automatically removed every cycle to eliminate possible carry over

|

|

Quiet Depressurization

|

N/A

- Unique exhaust air silencers significantly reduce noise levels

|

|

Energy Saving Design

|

N/A

- Integrated inlet and outlet filtration eliminates the need for external filter housings (An upstream coalescing filter may be required in some applications.)

- Advanced design limits regeneration purge air usage to approximately 15%

- Energy saving dewpoint monitoring option can save up to 60% during reduced inlet moisture loading

|

|

PLC Controls and Digital Display

|

N/A

- A clear digital display provides a full view of PLC operation and monitoring data

|

|

High Quality Construction

|

N/A

- 100% tested for leaks, proper operation and dewpoint performance

|

|

Easy to Install

|

N/A

- Easy to install and ready for use - package includes every-thing you need for either floor or wall mounting, and 3 power cables for operation virtually anywhere in the world (100 to 250 VAC, 50 or 60 Hz)

|

|

Easy to Maintain

|

N/A

- Patented, combined filter and desiccant cartridges

- Two service kits cover all your maintenance needs

- Built in inlet and outlet filters

- No special tools required

- No handling of loose desiccant

- No handling of contaminants

- Replace cartridges is less than 15 minutes

|

|

Warranty

|

N/A

- Peace of mind - a 5 year warranty comes standard with every D-Series1 dryer

|

|

Patented Combined Filter and Desiccant Cartridges

|

N/A

- Water separation, inlet and outlet filtration and desiccant are all integrated into a single cartridge (eliminates up to 3 external filters and drains).

- Built in inlet filter improves flow distribution and lowers pressure drop.

- Snow storm filled desiccant provides maximum adsorption capacity.

- Easy to replace cartridges simplify maintenance requirements.

|

|

PLC Controlled Operation

|

N/A

- The dryer is operated by a robust and reliable PLC control system, offering valuable features including 'power on', 'hours run' and 'service required' indicators.

- The PLC remembers where it stopped in the drying cycle to ensure consistently clean and dry air downstream.

- A standard energy saving feature starts and stops the dryer with a signal from the compressor or point-of-use equipment to eliminate purge loss when drying is not required.

|

|

Energy Saving Dewpoint Control Option

|

N/A

- With this option, a dewpoint sensor is incorporated into the dryer providing the ultimate in energy savings.

- The outlet dewpoint is constantly monitored, allowing the cycle time to be adjusted depending on the actual moisture load - saving valuable purge air.

|

|

Floor or Wall Installation

|

N/A

- Can be floor or wall mounted - simply by rotating the feet 90º.

|

|

Optimum Dewpoint Performance

|

N/A

- Air velocity (and therefore air to desiccant contact time) is carefully controlled via a pressure maintaining device to ensure optimum dewpoint performance.

|

|

Constant Flow and Pressure

|

N/A

- Pressure is equalized before switching columns to ensure uninterrupted compressed air at all times with no changes in pressure.

|

|

Reliable High Performance Valves

|

N/A

- Three way ball valves (NDL-010 to 050) or solenoid operated diaphragm valves (NDL-060 to 130) provide proven performance and reliability.

|

|

Maximum Corrosion Protection

|

N/A

- Anodized extruded high tensile aluminum columns provide maximum protection for corrosive environments.

|

|

System Performance

|

N/A

The advanced nano D-Series1 dryers use the pressure swing adsorption principle to efficiently dry compressed air. They use a heatless twin tower configuration housed in a modular design. Each column contains a unique (and patented) desiccant cartridge which incorporates inlet and outlet filtration.

Wet air from the compressor after-cooler enters the dryer and is directed into column A. Bulk liquids (water) and particles are removed by the filtration/separation stage, which is located on the inlet to the cartridge. Water is retained within the dryer until the column is regenerated, when it will be vented to atmosphere as it is depressurised. Following the filtration stage, air passes through the desiccant bed where any remaining moisture is adsorbed. Finally, the dry air passes through a particle filter, which retains any remaining desiccant particles that may have been carried through the system (<1 micron / ISO8573.1 class 2 for dust).

Simultaneously, a small amount of dry air is counter-flowed down through cartridge B and exhausted to atmosphere, removing the moisture and regenerating the desiccant.

The dryer is controlled by a PLC which periodically switches the solenoid valves when the compressor is running, reversing the function of each column and therefore ensuring the continuous supply of dry air.

Scan this tag with your mobile device to download a technical paper describing the performance limitations of typical twin tower desiccant dryers, and how the unique design of the nano D1 overcomes them to provide effective and efficient dehydration of compressed air.

|

|

Additional Information

|

N/A

Leading edge technology and more than 100 years of experience…nano-purification solutions, your world-class provider of state-of-the-art compressed air and gas solutions to industry.

Our commitment at n-psi is to work alongside our customers and provide unique solutions with the highest quality products to solve your specific challenges.

A wealth of experience and leading edge products are only part of the equation. n-psi realize that world-class customer service is the most important component to any successful business.

Experience. Customer. Service…n-psi

Designed for use at the point of application, nano dryers are an effective solution to the problems of contaminated compressed air.

Reliability is built in…and backed by our 5 year product warranty!

|

|

Note

|

N/A

- For rated flows at other inlet conditions or for -100 ºF (-70 ºC) dewpoint applications.

- If the dryer is to be installed downstream of an oil lubricated compressor, we recommend installing a nano F1 M01 (0.01 micron) coalescing filter immediately upstream of the dryer.

For Correction Factors - To calculate the maximum rated flow for any model at operating conditions other than those above:

Rated Flow x K1 x K2 x K3 = Rated Flow at new conditions (To be used as a rough guide only. All applications should be confirmed by n-psi. Contact us for sizing assistance).

|